|

|

|

|

#1

|

||||

|

||||

|

OT: Best material for exhaust studs

Spent the last two nights twisting off manifold fasteners and drilling out the remains. Still have 3 to go, in the head. Going to be a real pain, may have to pull the engine to do it. Wondering if I should replace with plain steel or stainless. Going to use studs and brass nuts rather than the stock bolts. Plain steel takes more torque and is what's generally used. Will stainless prevent seizing, or just be easier to break the next time?

|

|

#2

|

||||

|

||||

|

i'd use grade 8 steel hardware and plenty of high temp antisieze and hope for the best.

__________________

http://less-than-epic.blogspot.com/ |

|

#3

|

||||

|

||||

|

by the way, i've been there, and i dont envy you. it's a crap job to have to do. depending on the engine compartment and access, it may be a really crap job. good luck man.

__________________

http://less-than-epic.blogspot.com/ |

|

#4

|

|||

|

|||

|

What vehicle are you working on?

If this was head bolts you’d have more concern for strength than for the exhaust manifold, but it still has to be stout enough to do the job. Is there a high likihood that you will need to repair or dissamblemthis again? Even if you do, I don’t thinkmthere is any answer to making it easier next time. |

|

#5

|

|||

|

|||

|

Whatever ARP recommends for your engine

M |

|

#6

|

||||

|

||||

|

Winner, winner.

Did they seize due to ****e material, corrosion, or corrosion of ****e material. My guess is corrosion. ARP and anti-seize is the way to go. |

|

#7

|

|||

|

|||

|

I do not envy you for all the money in China. I had this issue on a 70 1/2 Z28

I just did the original rear rotors on a 2006 W220 with almost 200K on the clock and I could not get the set screw out and even drilling that and tapping was a PITA. The rotors were just inside Spec and was tempted to just throw pads on but Mr. Zimmermann said otherwise |

|

#8

|

|||

|

|||

|

Quote:

|

|

#9

|

||||

|

||||

|

Quote:

|

|

#10

|

|||

|

|||

|

Neat!

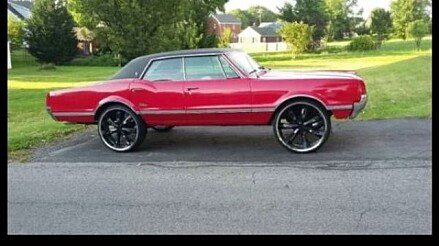

I hope you've modified it so it looks like this one  (jk, of course) (jk, of course)Around 30 years ago I drove with a buddy of mine way out to some teeny MO town to look at a '66 Cutlass convertible. It was powder blue and very cool. He did end up buying it. A bit later I bought his '70 Impala from him, drove it for a few years then sold it back to him.

|

|

#11

|

||||

|

||||

|

ARP has stud kits, no material specs but look like all steel hardware, $93, I'm not impressed.

I put the current exhaust system on this car, probably around 1990. I always use anti-seize on anything threaded but all 4 exhaust flange bolts twisted off. I don't think anti-seize makes much difference given the temps on exhaust systems. I'm thinking stainless studs with brass nuts may be the way to go, but am wondering if there's a reason why it's not commonly done. |

|

#12

|

|||

|

|||

|

Quote:

Was it this? https://www.permatex.com/products/lu...ize-lubricant/ Permatex® Nickel Anti-Seize Lubricant Category: Specialty Lubricants - Anti-Seize Protects metal parts from seizing and galling at temperatures up to 2400°F (1316°C). It is recommended where copper contamination must be avoided, under conditions of extreme pressure and temperature, and with stainless steel, titanium and nickel alloys. Application - Automobile Suggested Applications: Exhaust manifold bolts, exhaust system bolts, muffler clamps and tailpipe assemblies.

|

|

#13

|

||||

|

||||

|

Quote:

|

|

#14

|

||||

|

||||

|

Quote:

Last edited by oliver1850; 12-08-2017 at 01:39 AM. |

|

#15

|

|||

|

|||

|

My favorite cycling-related memory of the Impala is the size of the trunk - I could put my Trek 400 in there (I think it was a 62 ST) without removing the front wheel.

When I switched over to my '73 Charger I was bummed to find out that I'd have to remove the wheel to get it to fit. |

|

|

|