|

|

|

|

#46

|

|||

|

|||

|

Quote:

it would be nice if metal fatigue could be detected by monitoring changes in stiffness, but unfortunately its not that easy. |

|

#47

|

||||

|

||||

|

I downloaded and read the article cited as Ref. 10 in the Wikipedia entry on Fatigue Limit, "There is no infinite fatigue life in metallic materials" by C. Bathias.

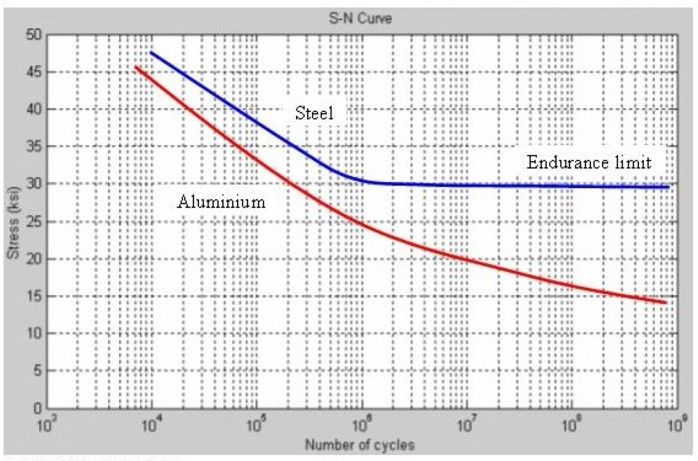

Bathias used a piezoelectric fatigue machine capable of accelerating fatigue testing by producing 10 to the tenth power stress cycles in less than a week. Bathias states that the concept of a fatigue limit is bound to the hypothesis of the existence of a horizontal asymptote (a line that continually approaches a given curve but does not meet it at any finite distance) on the S-N curve between 10 to the sixth power and 10 to the seventh power, so a sample that reaches 10 to the seventh power cycles and isn't broken is considered to have an infinite life. Bathias says this is a convenient and economical approximation, but is not a rigorous approach. Here is the S/N curve of steel and aluminum from the Wikipedia article on fatigue limit showing the near horizontal asymptote of steel (blue line):  Here is the S/N curve for medium strength steel from the Bathias article taken from ASM Atlas of Fatigue Curves, which Bathias says is an approximation.  Bathias goes on in the article to show that using a piezoelectric fatigue machine generating stress cycles at 20kHz to accelerate fatigue life testing out to 10 to the tenth power number of cycles, he produces fatigue failures below the fatigue limit (near horizontal asymptote). While I think this article probably does advance the knowledge of fatigue failures, I'm not convinced that it has any practical value when applied to fatigue of steel tube bicycle frames over decades of normal use. I could be wrong.

|

|

#48

|

|||

|

|||

|

Dont think so!

|

|

#49

|

|||

|

|||

|

From a materials perspective the steel should become brittle and crack if it fails from mechanical stress, which is what seems to happen, it would not make sense scientifically for steel to get softer.

|

|

#50

|

|||

|

|||

|

Except that the brittleness and flexibility are not directly related. You can harden steel and make it brittle, or anneal steel and make it soft, but it doesn't change its modulus (flexibility).

|

|

#51

|

||||

|

||||

|

Quote:

Many who should know better equate yield strength with stiffness. The bottom line is that for a given length, diameter, wall thickness and butting profile, a tube made of 1020 gaspipe with a yield strength of 205 MPa will have the same "stiffness" as a Reynolds 953 tube with a yield strength of 1450 MPa. Tubes made from stronger steel alloys can be drawn with thinner walls than weaker steels to make them lighter, but if they have the same diameter the stronger tube will be flexier because of the thinner walls. There are basically two ways to make a steel tube stiffer: 1) increase the wall thickness, 2) increase the tube diameter, or both. Jan Heine does a passable job of explaining the difference between stiffness and yield strength in THIS BLOG POST. |

|

#52

|

|||

|

|||

|

Isn't this conversation always on the theoretical level, anyway?

There are so many points of significantly more stress/flex before the frame itself, that how many average Joes can measurably and significantly fatigue a road bike frame? Think of spokes, hubs, tires etc. Aluminum handlebars? c'mon? Sure those do fail, however, rarely...When was the last I'm concerned about the fatigue cycles of aluminum handlebars conversation? While we mount noodle soft Giro D'Italia 64 cinelli bars on our classic steel frames. I've ridden pretty old cannondale's and they feel so imperceptibly different than new (unless accounting for a bike technological improvement). I've never known someone's frame to just blow-up while JRA. Is their any real concern about this? Sure, put a frame on a jig and stress it 5 million cycles and ka-boom, but in the real world? Every bike I've seen broken has either broken: 1. when expected because of massive impact/crash etc. 2. under the weight of a pretty heavy fella riding a pretty light bike. (not the right tool) 3. Due to what is a "fault" (ie manufacturing error, poor design) 4. improper assembly/maintenance and if that isn't 100% of the failures... it's 99.9% Theoretical I say. I've been riding Cannondale's for eons... but maybe I'm an outlier cause I only weigh 63kg.

__________________

cimacoppi.cc Last edited by rain dogs; 05-08-2014 at 07:23 PM. |

|

#53

|

|||

|

|||

|

for most of us, our only direct experience with fatigue is bending paper clips. Unfortunately, that's the mildest of mild steels, which has a really weird rupture behavior. Bicycle steels are more like aluminum, and they don't have huge elongations at yield before they rupture. There are probably changes in a bicycle frame over many years at minute levels, but it's unlikely to be noticable by a rider unless the bike frame suffers from macro cracks. Funny thing about that is that I had a couple of bikes crack at the bb shell and I didn't notice anything except the chain rubbing on the front derailleur. Cracks had to be almost halfway around the tube before that became evident.

|

|

#54

|

|||

|

|||

|

Yup. Two neat "around-the-house" experiments one can do with material failure modes are 1) the noticeable work-hardening you get with paper clips after a handful of cycles, and 2) the massive strain-rate sensitivity you get with Silly Putty.

|

|

#55

|

||||

|

||||

|

Well I learned a lot reading the stuff after my post. I wanted to make the point that metal fatigue is real, not some imagined thing, but there's no way I can relate it to bicycle frame behavior, nor did I (although I did post it in a "frame fatigue" related thread).

Personally I have no experience with riding multiple steel frames. I only ever had one steel framed serious bike and had it for two years, and it was about as bad a frame as you could get, Columbus Zeta tubing. I used to joke that Zeta was Italian for "Worst". Currently I think it's been reincarnated as a fixed gear frame under an aspiring frame-builder's torch. At any rate I've seen one Pinarello frame fail when the downtube broke in half. No crashes on it, it was a few months old. I sold the (new) frame to the rider, a friend, he was riding it, and suddenly his pedals were scraping the ground. That was a steel frame. I think the tube broke by the downtube shifter mounts so it was probably related to overheating the tube. However the tubing was intact at some point. Now I don't know what made it fail, if it wasn't fatiguing a weak part of the frame. I've had a few aluminum frames crack, chainstays (Specialized M2, Giant TCR, Cannondale original). I used them for years and with the TCR I was pretty overweight. I had two more aluminum TCRs after that with no problems (still have them in the basement). Now I understand that all cycles on aluminum frames "count". My main lesson is that a structure can fail even if the materials are still okay. The real world one for me is the Tappan Zee Bridge, which basically had a "use by date" that expired several years ago (2005 or so). Commuting on it was a bit sketchy as I'd keep an ear out on traffic reports for "hole in the deck in the second lane" etc. Chunks of the bridge fell out, and there was one day where I saw maybe 10-15 cars pulled over on the bridge with broken rims/etc, another 20-ish limping across the rest of the span on flat tires, and yet another 10-20 cars at the tolls changing flats, all from a 3 or 4 foot wide hole "in the deck". I was fortunate enough to miss that one, and another one that I was close enough to to be able to look down into it (I just saw bridge stuff, not water like I expected). I realize now that it may not be the steel/metal that is the issue but things like construction techniques/materials, corrosion, etc. A lot of the bridge has been fixed and apparently it's much better than it was in 2007, the last year I was commuting over it. I just read that they're starting construction of a new bridge now. Also I read there is no redundancy in the bridge, so if a single support failed the bridge could potentially fail. I also read that there are 8 floating things supporting the bridge (caissons, pressurized hollow concrete columns). This makes me want to take the Newburgh bridge rather than the TZ. |

|

#56

|

|||

|

|||

|

Quote:

Training and racing on the same bike, usually over 15K miles per year, just switch out wheels. Every time I broke a frame it wasn't a catastrophic failure. A couple of times it required a little reinforcement to get home, usually just ride carefully. In fact I broke a modern steel frame a couple of years ago and rode it home to figure out why it was shifting funny, cracked downtube. Frames were a "ride it until it fails" item for me. I only trashed 1 from a crash, however I was a little lighter then, 145 to 150lbs, depending on the time of year, about average for a roadie. I don't have any of these old broken frames, they were usually warrantied, but from memory, it seems that it was about half and half between tube failures and joint failures. I liked reading about the fatigue cycles because it made sense to me, I have been in races and watched a International level racer attack, the poor frame is moving all around, doing a hula dance. Enough movement that I could see it from behind while riding in survival mode. Granted, a good part of the movement was probably wheels, but not all of it. |

|

#57

|

|||

|

|||

|

Sean Kelly. 80% of his victories on a Vitus frame...so softer might be better?

|

|

#58

|

|||

|

|||

|

Quote:

I have an old Raleigh Professional, a steel frame. I still ride it and I doubt it will ever fail. If pro's say a frame is worn out or gone soft there are many other components that could account for the change in the feel of the bike other than the frame material. |

|

#59

|

||||

|

||||

|

Materials Science was my least favorite class ever.

|

|

#60

|

||||

|

||||

|

I bet the "my frame has gone soft" complaint has everything to do with just getting used to a bike both physically and mentally over the course of a season. The bike has not changed, the rider has adapted. If riders think that the myth of softening frames is true then they wrongly think that their feelings of adaptation is from the bike and not themselves. Just a thought.

__________________

Cheers...Daryl Life is too important to be taken seriously |

|

|

|