|

|

|

|

#1

|

||||

|

||||

|

Enve rim advice and spoke lacing question

Hey PL,

I'm putting together a track wheelset and have some questions before starting the build. The rims are enve classic 45mm(24 rear and 20 front) Hubs are dt swiss track. First question is if enve classic 45mm require a special type of spoke nipple? Or if a regular nipple is fine. My other question is regarding spoke pattern. I was thinking of 2x rear and radial front, but was wondering if I could do 2x front and 3x back with this little spokes or if it would even be worth it. Thanks, Calem |

|

#2

|

||||

|

||||

|

You should use the brass 3.2mm Enve internal nipples designed for the internal spoke beds. They are required to maintain warranty on the rims (not an issue in your case).

3x would be silly with 24h. Stick to radial/2x. Often track wheels are laced 2x on the front for additional laternal stiffness, but with a beefy Enve rim you'd have to be a real beast to notice the difference between lacing patterns. |

|

#3

|

||||

|

||||

|

Quote:

__________________

Chisholm's Custom Wheels Qui Si Parla Campagnolo |

|

#4

|

|||

|

|||

|

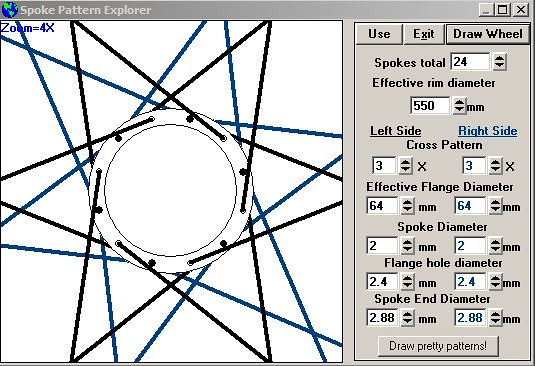

The spoke angle at the hub is:

Angle = (720 degress) x Crossings / Number of spokes For 24 spokes, 3 crossings means that the spokes will be at 90 degrees, or exactly tangential. As Old Potatoe said, this will result in the spokes overlapping a lot of flange. For 24 spokes, 2 crossings is the most common (60 degree angle). For 20 spokes, 2 crossings means that the spokes will be at an angle of 72 degrees. This is more possible, but there would still be a lot of flange overlap. For 20 spokes, 1 cross is the most common. Here's a list of the common crossings vs. number of spokes: 36 spokes: 3 or 4 cross 32 spokes: 3 cross 28 spokes: 2 or 3 cross 24 spokes: 2 cross 20 spokes: 1 or 2 cross 16 spokes: 1 cross 12 spokes: 1 cross |

|

#5

|

||||

|

||||

|

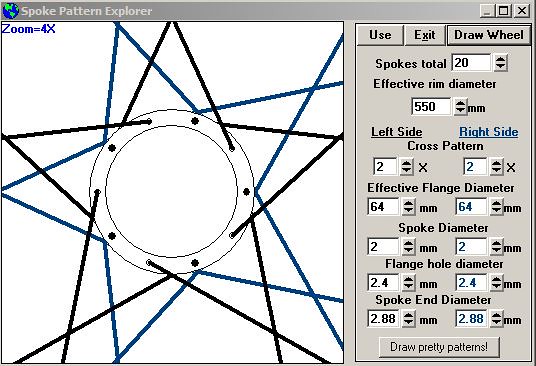

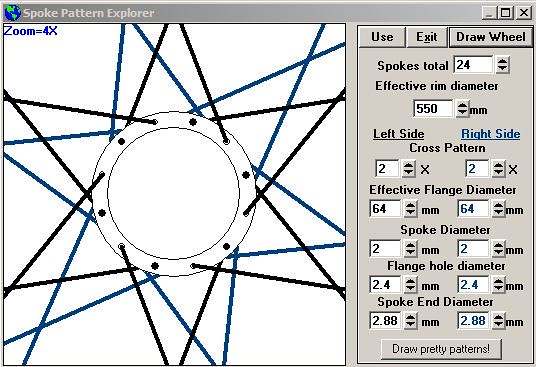

There is an old software program that visualized hub/spoke/rim patterns. You can still download it via archive.org at the link below. Useful if you are a hobbyist builder...

MachineHeadSoftwareSpokeCalculator Here are some samples (based on the OPs lacing ideas). You can see that the 24h3x is possible but you might have some overlap. DT 370 Front - 20h 2x  DT 370 Rear - 24h 2x  DT 370 Rear - 24h 3x

Last edited by Look585; 09-19-2017 at 07:13 PM. |

|

#6

|

|||

|

|||

|

2-cross front and rear.

Use the Pillar nipples that Enve recommends or provides. You can get them from other sources as well. They need a special wrench. You might think again about hub choices. I've not been particularly impressed by those hubs. Better to use traditional Dura Ace 7600 high flange track hubs, either single or double sided, or Phil Woods. Both are proven, bulletproof, with no slippage problems and no issues with bent axles or other failings that other track hubs are often prone to. |

|

#7

|

||||

|

||||

|

Quote:

__________________

Chisholm's Custom Wheels Qui Si Parla Campagnolo |

|

#8

|

|||

|

|||

|

3x solid as a rock

|

|

#9

|

|||

|

|||

|

You can't do 3x in a 20 or 24 spoked wheel because the spokes will be crossing over the adjoining spoke heads. The fewer the number of spokes, the faster you get to a near-tangent pull line with fewer crosses.

And it's been demonstrated by a number of wheel designers and expert builders that a change in cross count doesn't affect stiffness. This is also a track wheel set, remember. |

|

#10

|

|||

|

|||

|

Enve brass nipples are way softer than a DT or WS brass nipple, at it seems the case.

|

|

#11

|

||||

|

||||

|

I've repaired ENVE wheels with an inverted nipple w/o the notch..not sure where I got them..a while ago.

__________________

Chisholm's Custom Wheels Qui Si Parla Campagnolo |

|

#12

|

|||

|

|||

|

1 cross does a lot compared to radial, for wheels that bear torsional loads (rear wheels, front disc brake wheels). With 16 spokes, 1 cross produces the same 45 degree spoke angle as 2 cross with 32 spokes; and with 12 spokes, 1 cross proces the same 60 degree spoke angle as 2 cross with 24 spokes.

|

|

#13

|

|||

|

|||

|

Enve rim advice and spoke lacing question

I did this a while back with a set of Enve Classic 45s. The ERD for the Enve classics that I have in 24/28h is 566 (per Enve), correct for their internal nipple. Enve sells those on their website, and any shop with a QBP account can get them. Little pricier to buy individually from QBP; ENVE will sell a bag of a larger quantity (enough for one wheelset) to a shop at a slightly better price. Would be worth confirming the ERD with Enve, but for my version it was 566.

You'll definitely need the Enve internal nipple driver.

Last edited by MaraudingWalrus; 09-19-2017 at 06:55 PM. |

|

#14

|

|||

|

|||

|

Quote:

One thing I'd add is that you don't necessarily want to go to a tall (deep section) carbon rim on the track. It might sound good, but there's a lot of angular torque and while the rim is very strong within its axial plane, it can actually become pretty wobbly riding on bankings. You can stiffen it up again a bit with a tubular at fairly high pressure, but it's a bit unnerving to ride a really tall carbon rim on steep bankings. |

|

#15

|

||||

|

||||

|

Quote:

__________________

Chisholm's Custom Wheels Qui Si Parla Campagnolo |

|

|

|